| The system of bag weight accounting SUM-232 |

|

Weight accounting system - Function

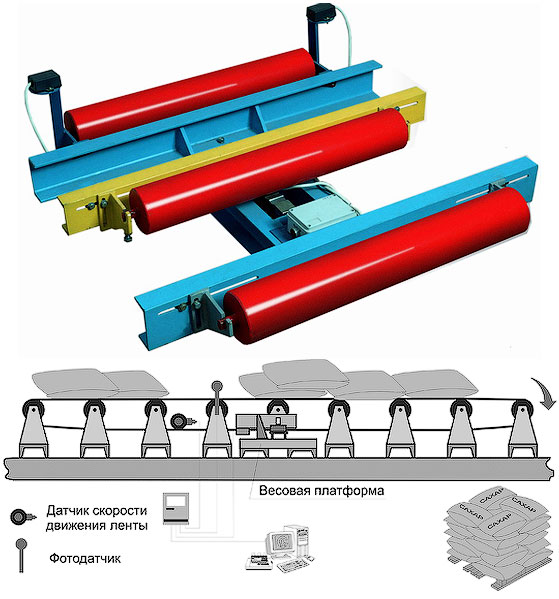

The weight accounting system is intended for calculation of bags and boxes with production, moving in a flow on conveyor belt at their transportation to the store room or shipment. The weight accounting system allows to eliminate finished product thefts, to accelerate the process of its shipment to the customer.

Weight accounting system - Structure

Weight accounting system - Functions

Weight accounting system - Operating principle The operating principle of the weight accounting system is grounded on weight measuring and speed of bag motion, moving on the weighing platform. Thus the bag presence on the belt is registered both on a signal from the platform load cells, and on a signal from the system photo sensors. The order of bag movement on the belt and their relative positioning does not influence on the exactitude of determination of bags number.

Weight accounting system - Technical data

Type of the indicating device....................... digital board Weight accounting system - Customers

Sugar plants of Ukraine, Russia, Belarus and Kazakhstan. Cement plants of Ukraine.

|