|

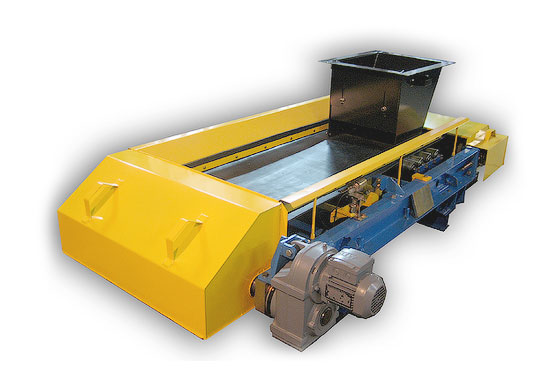

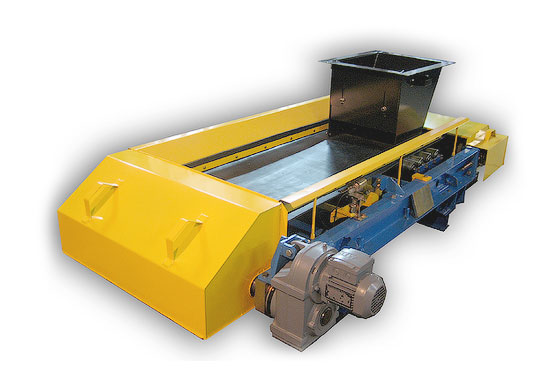

Belt weighing batcher - Function:

Belt weighing batcher is intended for continuous and portion batching of granular materials in mining and smelting, chemical, building and other branches.

Belt weighing batcher - Complement:

- conveyor with the electric drive;

- receiving hopper;

- weight measuring device;

- belt speed sensor;

- weighing processor;

- panel of the local control;

- device of the drive control

- portable board.

Belt weighing batcher - Function:

During the operation of the belt weighing batcher the weight measuring device continuously measures the material load, incomming from the receiving hopper on the conveyor belt. Simultaneously the speed of belt moving is measured on the signal from the speed sensor. Under this data the weighing processor calculates the actual capacity of the batcher, the value of the mismatch of capacity with the set one and formes the corresponding signal on the adjuster output of the frequency converter.

The converter changes the rotation speed of the drive, keeping the set capacity of the batcher. The weighing processor evaluates the value of the portion and the total amount of the material which has passed through the feeder.

Belt weighing batcher - Technical data:

Error limit in the mode of continuous batching.................. ± 1 % from LCL

Error limit of the total mass measuring.............................. ± 1 % from the measured mass

Lower capacity limit........................................................ 10 % from the nominal capacity

Nominal capacity:

DWL-650........................................................................................................ 10-100 t/h

DWL-800.........................................................................................................15-150 t/h

DWL-1000...................................................................................................... 20-200 t/h

DWL-1200........................................................................................................50-500 t/h

Nominal linear load:

DWL-650........................................................................................................27-270 kg/m

DWL-800........................................................................................................36-360 kg/m

DWL-1000......................................................................................................50-500 kg/m

DWL-1200......................................................................................................70-700 kg/m

Speed of belt moving ......................................................................from 0,05 to 0,6 km/s

Upper piece size............................................................................. not more than 200 mm

Overall dimensions:

DWL-650...........................................................................................2530х1470х850 mm

DWL-800............................................................................................2530х1670х850 mm

DWL-1000..........................................................................................2530х1930х850 mm

DWL-1200..........................................................................................3180х2070х900 mm

Mass, not more:

DWL-650................................................................................................................ 600 kg

DWL-800................................................................................................................ 770 kg

DWL-1000.............................................................................................................. 900 kg

DWL-1200.............................................................................................................1720 kg

Belt weighing batcher - Certificates:

Belt weighing batcher is certified as a measuring device in Ukraine (№ U 2923-09)

Belt weighing batcher - Customers:

Now there are manufactured and fixed more than 120 belt weighing batchers DWL in various industries. The basic customers:

«Doncement», «Cement of Donbass», "Dneprocement" - Ukraine.

«Rustavicement», "Sakcementy" - Georgia.

«Rybnitsky cement industrial complex» - Moldova.

«Asia cement» - Kazakhstan.

|